In Australia, the rules around RCD testing are set out in a national standard called AS/NZS 3760. It’s essential to understand how Recd Testing contributes to ensuring these life-saving devices are regularly checked to prevent electrical shocks.

How often you need to test an RCD depends entirely on the environment it’s in. A home might only need a simple push-button test every three months, while a busy construction site requires much more frequent, professional testing. These aren’t just suggestions—they are critical safety rules for any property.

Understanding Your RCD Testing Obligations

Getting your head around electrical safety regulations can feel a bit overwhelming, but the core requirements for RCD testing in Australia are actually quite straightforward. At the end of the day, these rules exist for one simple reason: to save lives.

A Residual Current Device (RCD), which most of us know as a ‘safety switch’, is your first line of defence against a fatal electric shock. But like any safety equipment, it’s only effective if you know it’s in good working order.

The go-to document for this is AS/NZS 3760, which details the minimum requirements for inspecting and testing electrical equipment that’s already in use. You can think of it as the official rulebook for electrical safety maintenance. It creates a consistent benchmark for safety, whether you’re in a suburban home, a corporate office, or a high-risk industrial workshop.

Who Needs to Comply

The responsibility for RCD testing doesn’t just fall on electricians. Depending on the property, a range of people are on the hook for making sure these devices are working correctly.

- Homeowners: While it’s not always a strict legal requirement in a private home, regularly testing your RCDs is just a common-sense way to protect your family.

- Landlords and Property Managers: They have a clear duty of care. This means ensuring their rental properties are electrically safe, and that absolutely includes functioning RCDs.

- Business Owners and Employers: Under Work Health and Safety (WHS) laws, providing a safe working environment is non-negotiable. For any business, this makes regular RCD testing a mandatory part of compliance.

Following the standard isn’t just about ticking a box or avoiding a fine. It’s about taking real, practical steps to create a safe space. An untested RCD is a gamble, offering a false sense of security while leaving people exposed to serious electrical risks.

Ultimately, these requirements are a practical roadmap. Once you understand who needs to test, how often, and why, you can take confident action. It’s about ensuring your property isn’t just compliant on paper, but genuinely safe for everyone.

What an RCD Does and Why Testing Is Critical

Before diving into the nitty-gritty of RCD testing requirements in Australia, let’s get a handle on what these devices actually do and why we can’t just install them and forget them. Think of a Residual Current Device (RCD) as a super-fast bodyguard for your electrical circuits.

In a healthy circuit, the amount of electrical current flowing out to power an appliance should be exactly the same as the amount flowing back. It’s a closed loop. But if a small amount of that current goes astray—maybe through a faulty appliance, a damaged cord, or worse, through a person—the RCD senses this imbalance immediately.

It then trips the circuit in a fraction of a second, typically between 20 to 40 milliseconds. That’s faster than the phase of an electric shock that can be fatal to a human heart, making it an absolute lifesaver.

Your Electrical System’s Silent Protector

Here’s a simple way to think about it. Imagine your wiring is like the plumbing in your house, and the electrical current is the water. An RCD is like an incredibly sensitive flow meter on your main water line. It’s constantly measuring the water going out to your taps and the water returning.

The very instant it detects a leak, even a tiny one, it slams the main valve shut. It doesn’t wait for a puddle to form or for the ceiling to collapse; it acts on the first sign of trouble. In an electrical circuit, that “trouble” is a potentially deadly electric shock or a fire.

The Hidden Danger of an Untested RCD

Having safety switches installed gives you peace of mind, but that security is completely hollow if the device doesn’t actually work when you need it most. Over time, the internal mechanics of an RCD can seize up from dust, moisture, corrosion, or just simple wear and tear. A safety switch that fails to trip is just a piece of plastic taking up space in your switchboard.

This is exactly why regular testing is not just a good idea—it’s essential. It’s the only way to be certain that your electrical bodyguard is still awake, alert, and ready to spring into action.

An untested RCD creates a false sense of security, which is arguably more dangerous than having no RCD at all. It’s a hidden failure waiting for an accident to happen, leaving people unknowingly exposed to the risk of electrocution or fire.

Without a proper testing schedule, you’re essentially betting that the device will work perfectly years after it was installed. The comprehensive RCD testing requirements in Australia exist to take that gamble off the table, ensuring your first line of defence against electrical hazards is always ready to do its job.

Decoding the AS/NZS 3760 Standard

When it comes to RCD testing, the rulebook we all work from is AS/NZS 3760. This document is the cornerstone for electrical safety compliance across Australia, laying out exactly how and when RCDs need to be checked.

Think of it less like a dense legal text and more like a national recipe for electrical safety. It gives us the specific methods, the right tools, and the correct timings to make sure every single RCD is doing its job properly. This standard cuts through the confusion, creating one clear benchmark for safety whether you’re in Perth or Parramatta.

Essentially, it removes the guesswork. It defines what “safe” actually means in practical, measurable terms, covering everything from the testing equipment itself to the records you need to keep.

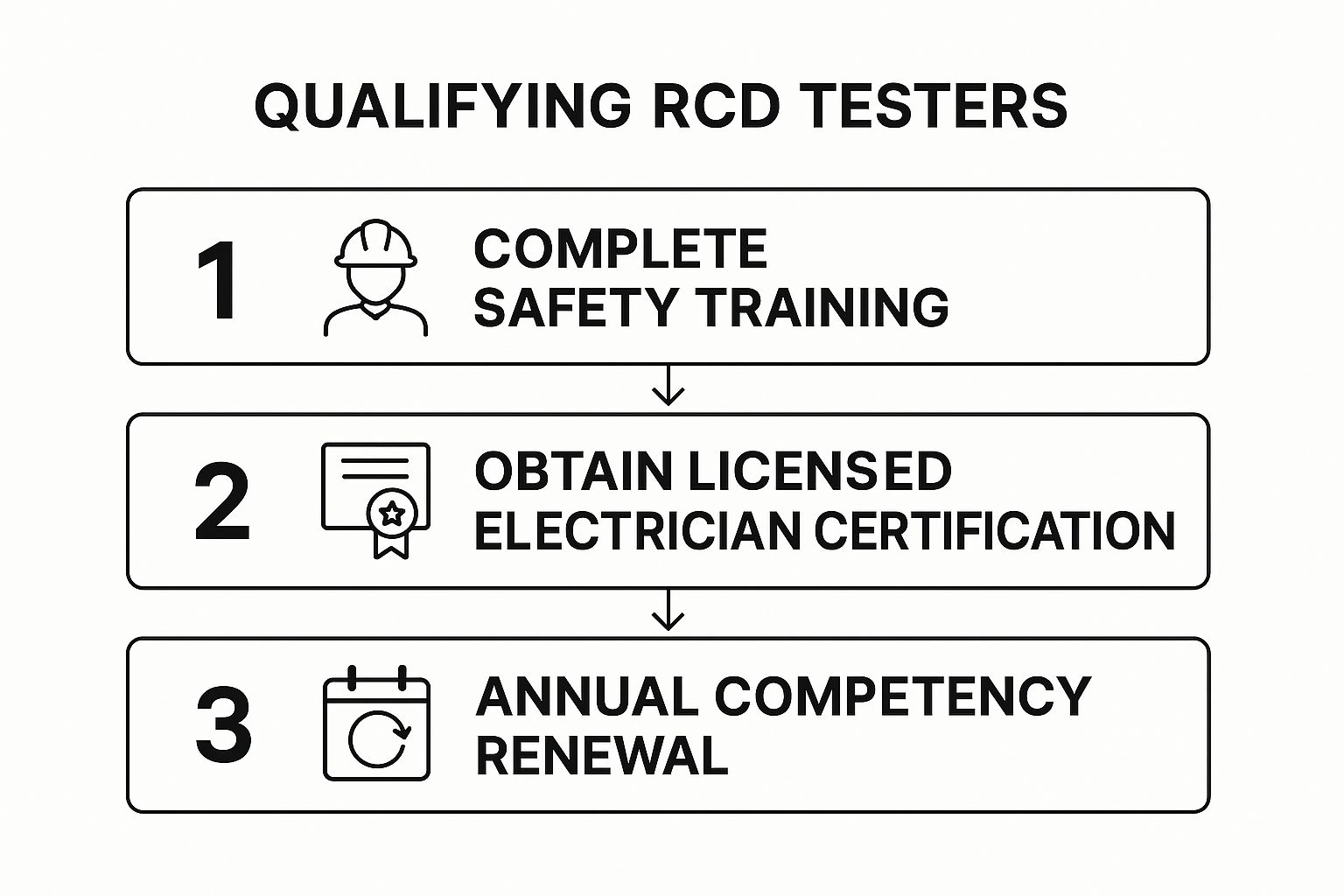

The Role of a Competent Person

A term you’ll see pop up constantly in AS/NZS 3760 is a “competent person”. This isn’t just a friendly suggestion; it’s a non-negotiable requirement for anyone carrying out these critical safety checks.

So, who is a “competent person”? They’re someone with the right training, qualifications, and real-world experience to perform the tests correctly and, most importantly, safely. They know how to handle the equipment without putting themselves or anyone else in danger.

While the standard doesn’t demand a specific license for every single task, for the more technical work like trip-time testing, this role is almost always filled by a qualified and licensed electrician. They don’t just know how to push buttons on a tester; they understand the results and can spot deeper electrical problems that might be lurking. This is what separates a quick DIY check from a formal, compliant safety test.

The Two Tiers of RCD Testing

The standard breaks down RCD testing into two distinct types. Each has a different job and is done at a different frequency.

- The Push-Button Test: This is the simple function check that anyone can—and should—perform regularly. You just press the ‘T’ or ‘Test’ button on the RCD unit. This makes sure the internal switch isn’t stuck and that it physically trips the power. It’s a basic test to confirm the device can trip.

- The Trip Time Test: This is the professional test, the one that requires a competent person and specialised testing gear. It measures the exact time, down to the millisecond, it takes for the RCD to cut the power when a fault is simulated. This is how we know the device trips fast enough to prevent a life-threatening electric shock.

This two-level system ensures every RCD gets both a regular ‘health check’ and a periodic, in-depth performance evaluation. The national standard, AS/NZS 3760:2022, sets different test schedules depending on the environment. A home might only need a push-button test every six months, but a high-risk workplace like a construction site will have much stricter requirements, often demanding professional trip time tests every six months or even more frequently.

Getting your head around these requirements is the first step to building a solid compliance strategy. Our detailed guide on AS/NZS 3760 offers more practical advice on maintaining your electrical safety obligations.

How RCD Testing Is Actually Performed

So, we know why RCDs need testing, but what does that actually look like on the ground? It’s not a single, one-size-fits-all process. RCD testing really breaks down into two distinct methods, each with a different but equally vital role.

One is a simple check anyone can do, and the other is a far more technical diagnostic that requires a qualified professional with specialised gear. Both are crucial for making sure your electrical safety net is not just in place, but is ready to react instantly when needed.

The User Push-Button Test

First up is the most common check: the push-button test. Think of this as a quick, routine fire drill for your RCD. It’s designed to make sure the internal mechanical parts haven’t frozen up or become stuck over time.

Every RCD, whether it’s in your switchboard at home or protecting equipment on a worksite, has a small button on it However, Marked with a ‘T’ for ‘Test’.

When you press this button, it creates a tiny, harmless current leak. This should be enough to instantly trip the RCD, cutting power to that circuit. If the switch flicks off, great—it passed. You can then just flip it back on to restore power. This simple test confirms the device can physically do its job, and it’s something every business owner should be doing regularly.

The Professional Trip Time Test

The second method is the one that really gets into the nitty-gritty: the trip time test. This is absolutely not a DIY task. It has to be carried out by a competent person—typically a licensed electrician—using a specifically calibrated RCD tester. This sophisticated device does something the push-button can’t.

It injects a very precise fault current into the circuit and measures, down to the millisecond, how long it takes for the RCD to cut the power.

Why is this so critical? Because an RCD has to react within a strict timeframe to prevent a fatal electric shock. For most common RCDs, this is typically well under 300 milliseconds. A slow RCD is as good as a failed RCD.

An RCD that passes the push-button test but fails the trip time test is a hidden danger. It proves the switch can move, but it’s not moving fast enough to save a life, making professional testing an indispensable part of your safety obligations.

This infographic gives you an idea of what’s involved for a professional to become qualified to perform these critical tests.

As you can see, becoming a “competent person” is a formal process involving proper training, hands-on experience, and ongoing validation of their skills.

What Happens If an RCD Fails

If an RCD fails either the push-button check or the more precise trip time test, it needs immediate attention. A failed device is a dud—it offers zero protection.

The faulty unit must be replaced by a licensed electrician as soon as possible. In the meantime, it should be clearly tagged as “out of service” to ensure no one mistakenly relies on it for their safety. You can find more details on professional RCD testing services that handle this entire process. Taking swift action is a non-negotiable part of meeting the rcd testing requirements australia has in place.

Proving Compliance With Proper Documentation

In the world of workplace health and safety, there’s an old saying that rings true: if it isn’t written down, it didn’t happen. Running regular RCD tests is only one half of the job; keeping meticulous records is what truly proves you’ve done your due diligence.

These records are your definitive proof of compliance. They’re what you’ll rely on to get through safety audits, back up insurance claims, or simply show regulators and your own team that you take electrical safety seriously. Without that paper trail, all your hard work is essentially invisible.

Think of your RCD logbook as the service history for your electrical safety system. Much like a car’s logbook details every oil change and tune-up, your RCD records provide a clear, chronological account of every inspection, test result, and any repair work carried out. This history is invaluable for tracking the performance and reliability of your safety switches over time.

The Anatomy of a Compliant RCD Log

A compliant record is much more than a quick note in a diary that says, “test done.” To satisfy the rcd testing requirements Australia has set out in standards like AS/NZS 3760, your documentation needs to be specific and thorough.

Your RCD test log, whether it’s a physical book or a digital file, must capture the following key details for every single device tested:

- Device Identification: A unique name or location for the RCD (e.g., “Main Switchboard, RCD for Level 2 Lights”).

- Test Date: The exact date the inspection was carried out.

- Test Result: A clear record of Pass or Fail.

- Trip Time: For the more technical ‘trip time’ test, the measured time in milliseconds (ms).

- Competent Person: The name and signature of the qualified person who performed the test.

- Next Test Due: The date the next scheduled test needs to happen.

Keeping detailed records transforms your compliance from a guess into a certainty. This paper trail is your first and best defence in the event of an electrical incident, proving you have actively managed your safety obligations.

The Role of Test and Tag

On top of keeping a formal logbook, the ‘test and tag’ system provides an immediate, on-the-spot visual check of an RCD’s status. After a successful test, a durable tag is attached directly to the switchboard or the RCD itself.

This tag acts as a quick, at-a-glance reference, instantly telling anyone who sees it that the device is compliant and when its next check is due. It effectively closes the loop between your detailed records and the physical equipment, creating total transparency and making it much easier to stay on top of your ongoing testing schedule.

The Real-World Impact of RCD Compliance

When we talk about RCD testing, it’s easy to get lost in the standards and schedules. But the real value isn’t found in a compliance certificate—it’s measured in the accidents that never happen. Sticking to the RCD testing requirements Australia mandates isn’t just about ticking boxes for the regulators; it’s one of the most effective ways to prevent a tragedy.

Think of it this way: every time an RCD passes its test, you’ve just confirmed your first line of defence against electrocution is armed and ready. This simple, routine check directly reduces the number of electrical shocks, injuries, and even fatalities in our homes and workplaces.

From Compliance to Prevention

The link between regular testing and genuine safety is undeniable. A working RCD is often the only thing standing between a minor equipment fault and a life-threatening electric shock or a devastating fire.

By following the testing intervals specified in AS/NZS 3760, you’re actively finding and fixing invisible hazards before they can cause harm. It’s a sobering thought, but industry data suggests that up to 40% of electrical faults in workplaces are stopped in their tracks by a properly functioning RCD. When you pair this with other safety measures, consistent testing leads to a massive drop in electrical injury claims each year.

Compliance isn’t an expense; it’s a powerful investment in protecting people and property. Every passed test builds a stronger safety culture, showing that you’re serious about looking after your employees, customers, and family.

This proactive approach transforms a simple requirement into a smart risk management strategy. It proves a genuine commitment to safety that goes well beyond the bare minimum, creating a safer environment for everyone involved. Understanding the cost of professional test and tag services reveals just how affordable this peace of mind really is.

At the end of the day, these standards and regulations exist for one simple reason: they make a life-saving difference, every single day.

Got Questions About RCD Testing? We’ve Got Answers

Even when you know the rules, practical questions always pop up. Let’s tackle some of the most common queries we hear from clients to clear up any lingering confusion.

What’s the Difference Between an RCD and a Circuit Breaker?

It’s a great question, and the answer is simple when you think about what each device is designed to protect.

A circuit breaker is there to protect your equipment and wiring. It trips when it senses an overload or short circuit—say, you’ve plugged in too many heaters at once. It cuts the power to stop wires from melting and preventing a fire.

An RCD, however, is all about protecting you. It’s constantly monitoring for tiny, almost imperceptible electrical leaks to earth. The moment it detects one—the kind that happens when current passes through a person’s body—it shuts the power off in a fraction of a second. This speed is what prevents a serious electric shock from becoming fatal.

You could say circuit breakers are the guardians of your property, while RCDs are your personal bodyguards. They do different jobs, but you absolutely need both for a truly safe electrical system.

Who Is Actually Allowed to Do the Professional Trip Time Test?

This isn’t a DIY job. The professional “trip time” test has to be carried out by what the standard, AS/NZS 3760, calls a “competent person”.

What does that mean in the real world? It means someone with the formal training, hands-on experience, and specialised testing equipment to do the job safely and get an accurate result. For all intents and purposes, this is a licensed electrician, specifically one who’s well-versed in testing and tagging procedures. Trying to do this yourself isn’t just a compliance issue; it’s incredibly dangerous.

Whoops, I Missed a Test Date. What Now?

Don’t panic, but do act fast. If you’ve realised a scheduled test has been missed, the priority is to get it done immediately.

An untested RCD is a big unknown in your safety system. The longer it goes without being checked, the higher the potential risk. Get in touch with a qualified technician right away to perform the necessary tests. This will get you back on the right side of compliance and, more importantly, restore your peace of mind that everything is working as it should.

At Safety First Test and Tag and Fire Safety, we take the guesswork out of electrical safety and compliance. Our certified technicians offer expert RCD testing services across Geelong and Melbourne, making sure your workplace is fully protected and meets every Australian standard. Ready for a proactive safety plan? Visit us at https://safetyfirsttesttag.com.au for a free quote.

Article created using Outrank