In Victoria, the rules around RCD testing aren't just suggestions—they're a non-negotiable part of keeping people safe from electrical hazards. Think of it as a legal duty of care. WorkSafe Victoria and other authorities mandate these checks to make sure these life-saving devices are always in working order, ready to prevent a serious electric shock or fire.

Your Guide to RCD Safety and Compliance in Victoria

Trying to get your head around electrical safety regulations can feel a bit overwhelming, but when it comes to RCD testing, it’s something you absolutely need to get right. Picture a Residual Current Device (RCD) as a hyper-vigilant bodyguard for your electrical circuits. Its one job is to detect the tiniest current leak and shut the power off in a fraction of a second—long before it can cause a fatal shock.

This guide will break down exactly what you need to do to stay compliant. The rules aren't the same for everyone; a family home has very different requirements compared to a construction site or a bustling commercial kitchen. It all boils down to the level of risk in that specific environment.

Who Sets the Rules and Why

The main authorities driving these regulations are WorkSafe Victoria and Energy Safe Victoria. Their entire focus is on preventing harm, and they know that faulty electrical equipment is a major risk. By enforcing regular RCD testing, they ensure this critical safety net is always functional.

For business owners and landlords, this means compliance is about more than just dodging fines. It's about fulfilling your fundamental responsibility to keep your employees, tenants, and customers safe.

An RCD is designed to detect even the smallest leak of electrical current and shut off the power almost instantly. This rapid response is what prevents a minor electrical fault from becoming a tragedy, making consistent testing an essential practice.

Understanding Your Specific Obligations

The frequency and type of testing required depend entirely on where your RCDs are installed. For instance, the RCD testing requirements in Victoria for a high-risk environment like a construction site are far more demanding than for a standard office space.

Typically, a competent person can perform a simple push-button test every six months. However, a more technical "trip time" test, which measures the RCD's reaction speed, must be conducted by a licensed electrician. For those higher-risk environments, these professional inspections are often required more frequently to manage the elevated dangers. You can learn more about these specific compliance timelines to ensure you're meeting your legal duties.

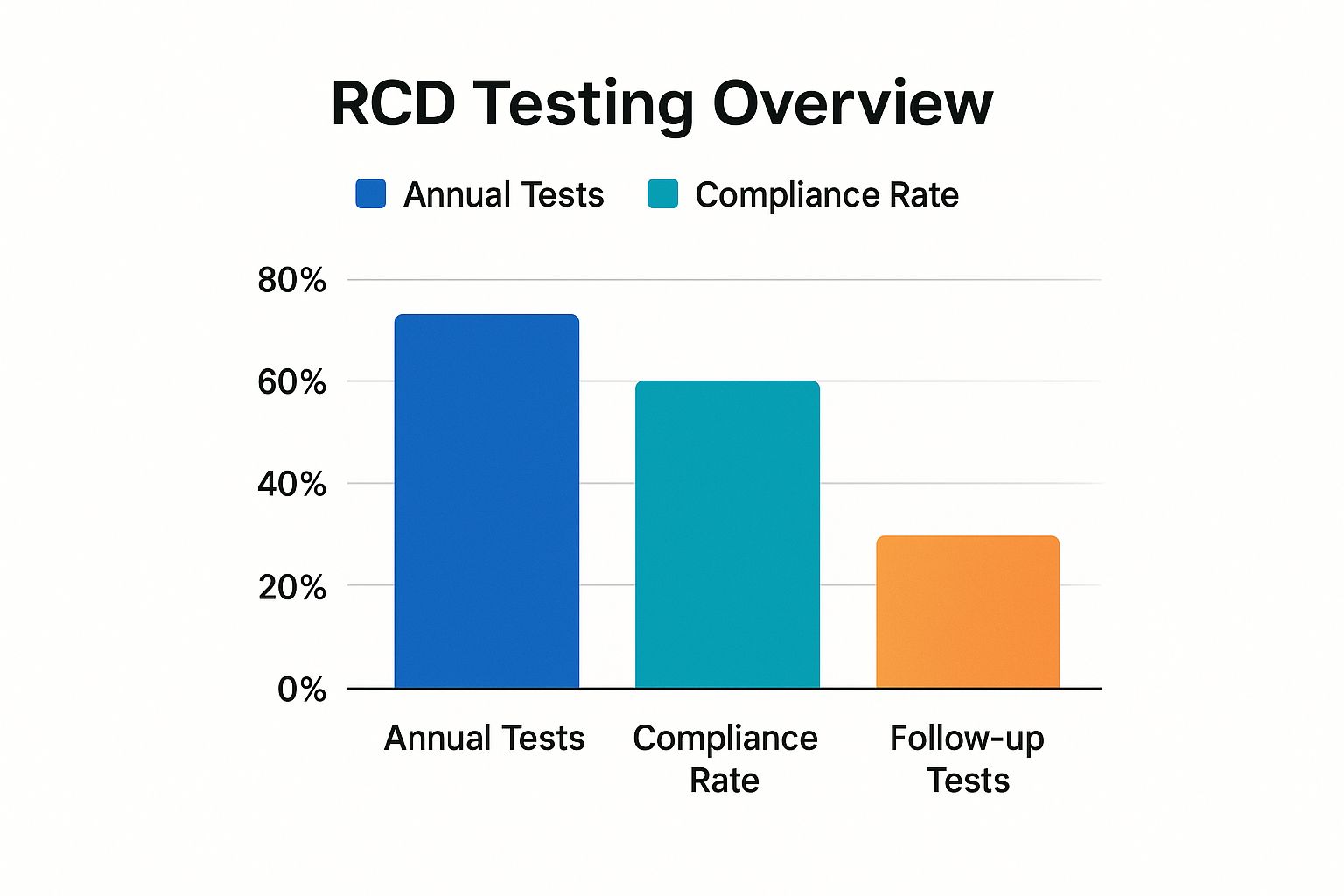

The image below gives a high-level look at RCD testing compliance and follow-up rates.

This data shows that while most required annual tests get done, there’s still a noticeable gap in overall compliance, which really highlights the need for greater awareness.

To make things clearer, I've put together a table summarizing the testing intervals for different environments. This should give you a solid starting point for making sure your property is safe, compliant, and protected.

Quick Guide to RCD Testing Frequencies in Victoria

This table offers a snapshot of the required RCD testing intervals for various environments across Victoria, helping you quickly identify your specific obligations.

| Environment Type | Push-Button Test Frequency (User/Competent Person) | Trip Time Test Frequency (Licensed Electrician) |

|---|---|---|

| Offices, Low-Risk Workplaces | Every 6 months | Every 24 months |

| Commercial Kitchens, Factories | Every 6 months | Every 12 months |

| Construction & Demolition Sites | Every 3 months | Every 12 months |

| Manufacturing & Assembly | Every 6 months | Every 12 months |

| Residential Tenancies | N/A (Landlord ensures functionality) | Every 24 months (as per VURT regulations) |

Remember, this table is a guide. It's always best to consult with a licensed electrician to confirm the exact requirements for your specific situation and stay on the right side of the law.

How RCDs Protect You and Why Testing Is So Important

To get why regular testing is non-negotiable, you first need to understand what an RCD actually does.

Picture your building's electrical wiring as a closed loop of water pipes. The RCD is like a hyper-sensitive monitor on that loop, constantly checking that the amount of current going out is exactly the same as the amount coming back in.

The second it senses a tiny imbalance—a 'leak' where current is escaping to the ground, maybe through someone touching a faulty kettle—it slams the power off. It does this in a fraction of a second, long before a dangerous amount of electricity can pass through a person. This lightning-fast reaction is what separates it from a standard fuse or circuit breaker, making it a life-saving device.

Without a working RCD, that same electrical fault could lead to a severe electric shock or even spark a fire. It’s your silent guardian, and it has to be in perfect working order.

The Two Pillars of RCD Testing

Making sure your RCD is ready to jump into action comes down to two different kinds of tests. Both are essential for meeting the rcd testing requirements victoria has in place, and you can't substitute one for the other. One is a quick, simple check, while the other is a precise, technical measurement.

It's a bit like looking after your car's brakes. You might tap the pedal before driving to feel the pressure is there (the simple test). But you trust a mechanic to professionally measure the brake pads and check the stopping distance to confirm it’s genuinely roadworthy (the technical test).

The rulebook for all of this is the Australian Standard AS/NZS 3760. This document lays out the exact methods, testing schedules, and record-keeping obligations to ensure RCDs are maintained properly and safely across all workplaces.

The Push-Button Test: A Simple Mechanical Check

The first and most basic check is the push-button test. This is a simple physical test to make sure the RCD's internal switch isn't jammed or frozen in place. You’ll see a small button on the unit, usually marked with a "T" or "Test".

Here’s how it works:

- Firmly press the test button.

- The RCD should immediately trip, cutting power to that circuit.

- You then just flick the switch back on to restore power.

If the RCD doesn't trip, you have a problem. Its internal parts are likely compromised, and it can no longer be trusted to protect you. This test doesn't tell you how fast it trips, just if it can. It’s a pass/fail check that any competent person can perform.

The Trip Time Test: A Professional Performance Measurement

The second, more specialised test is the trip time test. This one requires a licensed electrician with calibrated testing equipment. They use their gear to simulate a real electrical fault by introducing a very small, controlled leakage current.

The instrument then measures, down to the millisecond, how quickly the RCD cuts the power. Under AS/NZS 3760, a standard RCD must trip within a specific window (typically under 40 milliseconds for the most common types) to be considered safe. An RCD that’s too slow is just as dangerous as one that doesn't work at all.

This professional test gives you documented proof that your RCD not only functions but is fast enough to actually prevent injury. It’s an essential step in fulfilling your legal duties and ensuring your workplace is electrically safe.

RCD Requirements for Your Specific Environment

When it comes to RCD testing, there's no "one-size-fits-all" rule. The law smartly ties the frequency and detail of inspections directly to the level of risk in a particular environment. This practical approach means the highest level of protection is applied exactly where it's needed most.

Think of it like road rules. A quiet suburban street has a much lower speed limit than a multi-lane freeway because the risks are worlds apart. In the same way, the RCD testing requirements Victoria enforces for a dynamic construction site are far more strict than for a predictable office.

Let's walk through the specific obligations for different environments, from rental homes to high-risk industrial sites. Getting these details right is about more than just ticking a compliance box—it's about genuinely keeping people safe.

Residential and Landlord Obligations

For homeowners, checking your RCDs is simply a matter of personal safety. While there isn't a legally mandated testing schedule for owner-occupiers, giving them a regular push-button test is a very smart habit to get into.

For landlords in Victoria, however, the story is quite different. The Residential Tenancies Act places a clear duty of care on property owners to ensure their rental is electrically safe. This isn't a recommendation; it's a legal necessity that includes professional RCD testing.

Here’s what landlords need to do:

- Initial Safety Check: Before a new tenant moves in, you must ensure all RCDs are correctly installed and working perfectly.

- Regular Inspections: You need to get a licensed electrician in to conduct a full safety check, including a proper RCD trip time test, at least every two years.

- Record Keeping: Always keep detailed records of these electrical safety checks. This is your proof of compliance if anything ever goes wrong.

Following these rules protects your tenants and gives you a clear framework for meeting your legal duties, which minimises your liability and provides genuine peace of mind.

Treating RCD testing as a non-negotiable part of property maintenance isn't just about following the law. It builds trust with your tenants and shows you're committed to their wellbeing.

Commercial Offices and Low-Risk Workplaces

In places like offices, retail shops, and other low-risk commercial settings, the electrical hazards are generally lower than in an industrial plant. The equipment is typically kept in clean, stable conditions, which reduces the chances of damage or faults.

But "low-risk" doesn't mean "no-risk." Compliance is still mandatory. The testing requirements here strike a balance, focusing on consistent checks without the intensity needed for tougher environments.

For a typical office or retail space, the schedule looks like this:

- Push-Button Test: A competent person on your team should perform this simple check every six months.

- Trip Time Test: A licensed electrician must be brought in to conduct this professional test every 24 months (two years).

This two-tiered approach ensures the devices are regularly checked for basic mechanical function, while also getting a precise performance measurement at a sensible interval.

High-Risk Workplaces and Hostile Environments

Now we’re on the freeway of electrical risk. Places like factories, busy commercial kitchens, workshops, and even some healthcare facilities are classed as "hostile" environments. Here, electrical gear is constantly exposed to things like moisture, dust, heat, vibration, and just plain heavy use, all of which dramatically increase the chance of something going wrong.

Because the potential for a serious electrical incident is so much higher, the RCD testing requirements Victoria mandates are significantly more stringent.

The testing frequency is ramped up to match this elevated risk:

- Push-Button Test: This needs to be done every six months by a competent person.

- Trip Time Test: A licensed electrician has to perform this critical test every 12 months.

This annual professional inspection is vital. It confirms that the RCDs can handle the tough conditions and still trip in a fraction of a second when they're called upon.

Construction and Demolition Sites

Construction and demolition sites are the absolute peak of electrical risk. You've got power tools, temporary wiring, and portable equipment being dragged through water, mud, and dust while getting knocked about constantly. It’s the ultimate hostile environment for anything electrical.

As you’d expect, these sites have the most rigorous RCD testing schedule of all. On any Victorian construction site, frequent testing isn’t just a good idea—it’s a critical defence against serious injury or death. As these insights on RCD testing compliance explain, staying on top of this doesn't just protect workers; it also helps you secure the necessary compliance certificates for insurance and site operations.

- Push-Button Test: This must be performed every three months on fixed RCDs. For portable RCDs, a daily check before use is an established best practice.

- Trip Time Test: A full professional test by a licensed electrician is required every 12 months.

This level of constant vigilance is non-negotiable. It provides an essential safety net in a place where the electrical landscape can change from one day to the next.

Getting to Grips With the Standards and Legal Obligations

To stay on the right side of RCD testing in Victoria, you need to understand the official framework that governs electrical safety. This isn't just about ticking boxes; it's a structured system built to prevent serious accidents. The entire process is guided by specific standards and overseen by key authorities who make sure these life-saving measures are actually being followed.

At the helm, you have two main bodies: Energy Safe Victoria (ESV) and WorkSafe Victoria. Think of ESV as the state's technical expert for all things electricity—they set the safety benchmarks for equipment and installations. WorkSafe Victoria, on the other hand, is the on-the-ground enforcer for occupational health and safety, focused on keeping people safe at work.

Together, they create and uphold the legal duties that businesses, landlords, and tradies must adhere to. Their shared mission is simple: to reduce electrical risks everywhere, from family homes to high-risk industrial sites.

The Official Rulebook: AS/NZS 3760

The cornerstone for all testing procedures is the Australian/New Zealand Standard AS/NZS 3760. This is the go-to document that lays out the exact protocols for inspecting and testing electrical equipment after it's been put into service. It provides clear, practical instructions on everything from basic visual checks to the highly precise timing tests for RCDs.

This standard isn't just a list of suggestions; it's the benchmark that licensed electricians use to certify your compliance. It defines the pass/fail criteria for an RCD's trip time and specifies the records you’re legally required to keep. While Victoria has its own specific regulations, you can’t get around the foundational principles of AS/NZS 3760. To see the bigger picture, it's worth exploring the RCD testing requirements across Australia.

Competent Person vs. Licensed Electrician

A critical distinction in the regulations is who is qualified to perform certain tests. This isn't a grey area—the rules are crystal clear to ensure safety is never compromised by a lack of expertise.

- Competent Person: This is someone with the right training and experience to handle basic checks, like the simple push-button test. They know the equipment and can safely see if the RCD trips, but they aren't qualified to perform technical diagnostics.

- Licensed Electrician: A licensed sparkie is required for the more complex trip time test. They have the qualifications, experience, and properly calibrated equipment needed to measure an RCD’s reaction speed down to the millisecond and certify that it's up to standard.

In short, a competent person can check if an RCD works, but only a licensed electrician can verify how well it works and officially sign off on its safety. This ensures the most critical performance tests are always handled by a qualified professional.

The Critical Role of Record Keeping

Your paperwork is your ultimate proof of compliance. If an incident happens or a WorkSafe Victoria inspector drops by, your records will be the first thing they ask for. Having meticulous logs shows you’ve taken your duty of care seriously.

For every RCD test, your records must include:

- The date of the test.

- The name of the person who performed the test.

- The outcome (pass or fail).

- The measured trip time (for professional tests).

- A date for the next scheduled test.

These records must be kept safe for seven years. Failing to maintain accurate and up-to-date documentation can lead to significant penalties, even if you’ve had the tests done correctly.

The Consequences of Getting It Wrong

Ignoring these obligations can have serious consequences. The penalties for non-compliance can range from hefty fines handed out by WorkSafe Victoria to potential prosecution if a serious incident occurs. On top of that, most insurance policies require you to comply with all relevant Australian Standards. A failure to do so could void your coverage entirely, leaving you personally on the hook for any damages.

It’s no secret that RCD testing is vital for reducing electrical incidents. An ESV review in 2021 underscored this by integrating RCD checks into mandatory electrical safety assessments, especially for rental properties, reinforcing just how crucial these devices are.

A Practical Checklist for RCD Compliance

Knowing the rules is one thing, but putting them into practice is what keeps people safe. Think of this as your roadmap for staying on top of your RCD compliance duties and making sure these critical devices are always ready to do their job.

Your first move should always be to bring in a professional. The technical trip time tests must be done by a qualified and licensed electrician. It’s a good idea to find someone who specialises in workplace safety, as they'll be up to speed on the specific RCD testing requirements Victoria has for your type of environment.

When the electrician is on-site, they’ll run through a series of checks. This includes a visual inspection for any obvious signs of damage, followed by the all-important trip time test using properly calibrated equipment. Afterwards, they’ll hand you a compliance report that details the results for every RCD tested—this is your official legal record, so keep it safe.

Performing the User Push-Button Test

Between those professional check-ups, you have a small but important role to play. The push-button test is a quick mechanical check you can—and should—do yourself. It’s designed to make sure the RCD’s internal switch isn’t jammed or stuck.

Here’s the right way to do it:

- Give a Heads-Up: Let everyone in the building know you’re about to do a test, as it will cut the power to any circuits connected to that RCD.

- Press the 'Test' Button: Find the button, often marked with a 'T', and press it firmly. You should hear and see the switch flick instantly to the 'Off' position.

- Check the Power: Make sure an appliance on that circuit (like a lamp or a computer) has actually turned off.

- Reset and Restore: Simply flip the switch back to the 'On' position to get the power back up and running.

What if it doesn't trip? That RCD needs to be replaced by a licensed electrician without delay. This simple, regular check is a fundamental part of keeping your workplace safe.

A successful push-button test is a good sign—it means the RCD's mechanical parts aren't seized. But it tells you nothing about its reaction speed. That’s why the professional trip time test is absolutely essential and non-negotiable.

Understanding RCD Failures and Next Steps

Even with the best maintenance, RCDs can sometimes fail. Knowing why can help you spot potential problems early. The usual suspects are old age, moisture getting inside, a build-up of dust and grime, or damage from a power surge.

If an RCD fails a professional test, it’s no longer compliant and isn't providing the protection you think it is. Your electrician will tell you it needs to be replaced immediately. Don’t put this off. A faulty RCD offers a false sense of security and exposes everyone to the risk of a serious electric shock. Working with a trusted provider for professional RCD testing services means you'll get clear, actionable advice and a fast solution for any failed units.

An RCD can fail a test for several reasons, each with serious implications. The table below breaks down what these failures mean and what you need to do.

Diagnosing Common RCD Faults

| Reason for Failure | What It Means for Your Safety | Immediate Action Required |

|---|---|---|

| Slow Trip Time | The RCD isn't reacting fast enough to prevent a serious electric shock. It's a ticking time bomb. | Must be replaced by a licensed electrician immediately. |

| Fails Push-Button Test | The internal switching mechanism is seized or broken. It simply won't trip in an emergency. | Must be replaced by a licensed electrician immediately. |

| Visible Damage | Cracks, charring, or burns on the unit point to internal damage, making it completely unreliable. | Isolate the circuit straight away and have an electrician replace the RCD. |

Ultimately, any RCD failure is a red flag that demands immediate attention to ensure your electrical systems are safe and compliant.

Common Questions About RCD Testing in Victoria

Even with the rules laid out, practical questions always pop up when it's time to deal with RCD compliance on the ground. The world of RCD testing requirements in Victoria has its nuances, and sorting through them is the key to managing your electrical safety with confidence.

Let's tackle some of the most common questions we hear from clients. We'll give you clear, straightforward answers to clear up any lingering confusion, from basic definitions to what to do in a real-world scenario.

What Is the Difference Between an RCD and a Circuit Breaker?

This is easily the most common point of confusion we encounter, but the distinction is critical. They both live in your switchboard and they both cut the power, but they are designed to protect against completely different dangers.

Think of a circuit breaker as a bodyguard for your building’s wiring and appliances. Its one and only job is to watch for overloads and short circuits. If you plug too many heaters into a single circuit, or a wire frays and faults, the circuit breaker trips. This stops the wiring from getting dangerously hot and potentially starting a fire. It protects the equipment.

An RCD, on the other hand, is a personal bodyguard for you. It isn’t looking for big power surges; it’s looking for tiny, almost undetectable leaks of electrical current—the kind that occurs when electricity finds a path to the ground through a person. This is what causes a life-threatening electric shock, a hazard a normal circuit breaker is completely blind to.

A circuit breaker saves your property from fire. An RCD saves your life from electrocution. Any modern, safe switchboard absolutely needs both working in tandem.

How Much Does Professional RCD Testing Cost in Victoria?

Pinning down a single, fixed price for RCD testing is tricky because the final cost hinges on a few key factors. The total investment really depends on the size of your site, how many RCDs need testing, and how easy it is to access the switchboards.

Naturally, a small office with a single switchboard will be a much quicker and more affordable job than a sprawling industrial factory with multiple distribution boards scattered across the premises. Some technicians might bill per RCD, while others will package it into a complete site inspection.

The best approach is always to request a detailed quote from a qualified professional. For a deeper dive into the factors that influence pricing, our guide on test and tag costs offers some great insights that apply here too. While costs generally fall in line with standard electrician rates, it's a small price to pay for verified safety and total peace of mind.

What Should I Do if an RCD Trips Frequently?

An RCD that keeps tripping isn't a sign that the RCD is broken. More often than not, it's a sign that it's doing its job perfectly. It has detected a genuine, and potentially dangerous, electrical fault somewhere in the circuit or within an appliance plugged into it. While some call this "nuisance tripping," it’s actually a critical warning sign you can't afford to ignore.

Here’s a simple process you can follow to find the culprit:

- Unplug Everything: Go to the affected area and unplug every single appliance from the power points on that circuit.

- Reset the RCD: Head to your switchboard and flip the RCD switch back into the 'On' position. If it stays on, you can move to the next step.

- Test One by One: Go back and start plugging in your appliances and turning them on, but do it one at a time. The moment you plug in the faulty device, the RCD will trip again.

- Isolate the Fault: You've found it! Unplug that appliance and get it repaired or replaced by a professional.

If the RCD keeps tripping even when nothing is plugged in, the fault is likely in the building's permanent wiring. If that happens, you need to call a licensed electrician immediately. Never, ever ignore a frequently tripping RCD.

Do Portable RCDs Need to Be Tested Too?

Yes, one hundred percent. Portable RCDs—the kind you see on extension leads used on construction sites or with equipment like pressure washers and grinders—are subject to the very same testing standards under AS/NZS 3760.

In fact, testing them is arguably even more important. Because they are constantly being moved, dropped, and used in tough, dirty environments, they are far more likely to get damaged than a fixed unit sitting safely in a switchboard.

The testing rules for portable RCDs are just as strict:

- They need regular push-button tests, which is often best practice to do before every single use.

- They must have a professional trip time test done at the same intervals as any other appliance in their environment, which is typically every 12 months for higher-risk workplaces.

For workers using power tools in challenging conditions, these portable units are often their only line of defence against electric shock. Making sure they work flawlessly isn't just about compliance; it's a fundamental part of keeping your worksite safe.

At Safety First Test and Tag and Fire Safety, we simplify electrical and fire safety compliance for businesses across Geelong, Melbourne, and the SurfCoast. Our certified technicians provide thorough RCD testing, detailed reporting, and proactive management to ensure you meet all your legal obligations and keep your team safe. Request a free quote today to see how we can help protect your workplace.

https://safetyfirsttesttag.com.au

Article created using Outrank