Certified Electrical Testing and Tagging Services

Electrical safety is not just a ‘nice to have’—it is a mandatory requirement under Australian WHS legislation. At Safety First Test and Tag, we ensure your workplace remains safe and compliant with the national standard, AS/NZS 3760:2022. Whether you run a corporate office in Melbourne or a construction site in Geelong, our certified technicians provide rigorous inspection and testing for all plug-in appliances

Our 4-Step Electrical Testing Process

Many budget providers skip steps. We don’t. We follow a strict 4-stage safety protocol for every single item:

Visual Inspection: 90% of faults are visible. We check for damaged leads, cracked casings, discolored plugs (overheating), and loose guards. If it looks unsafe, we fail it immediately.

Electrical Testing: We use calibrated Portable Appliance Testers (PAT) to measure what the eye can’t see.

Earth Continuity: Ensuring the grounding pin is actually connected.

Insulation Resistance: Checking that the internal wiring is fully insulated to prevent shock.

Polarity: Ensuring Live and Neutral wires aren’t crossed (crucial for extension leads).

Tagging: If the item passes, we apply a durable, barcoded tag showing the Test Date, Next Due Date, and the Technician’s ID.

Reporting: You receive a comprehensive Digital Asset Register. This PDF report lists every item, its barcode, and the specific test results—essential for WorkSafe audits and insurance claims.

What Equipment Do We Test?

Our scope covers any single-phase or 3-phase device that plugs into a standard power outlet, including:

IT Equipment: Computers, monitors, printers, and server racks (Class I and II).

Kitchen & Tearoom: Kettles, microwaves, fridges, and coffee machines.

Construction Tools: Drills, grinders, chargers, and portable RCD boxes.

Industrial Machinery: 3-Phase equipment, welders, and heavy-duty extension leads.”

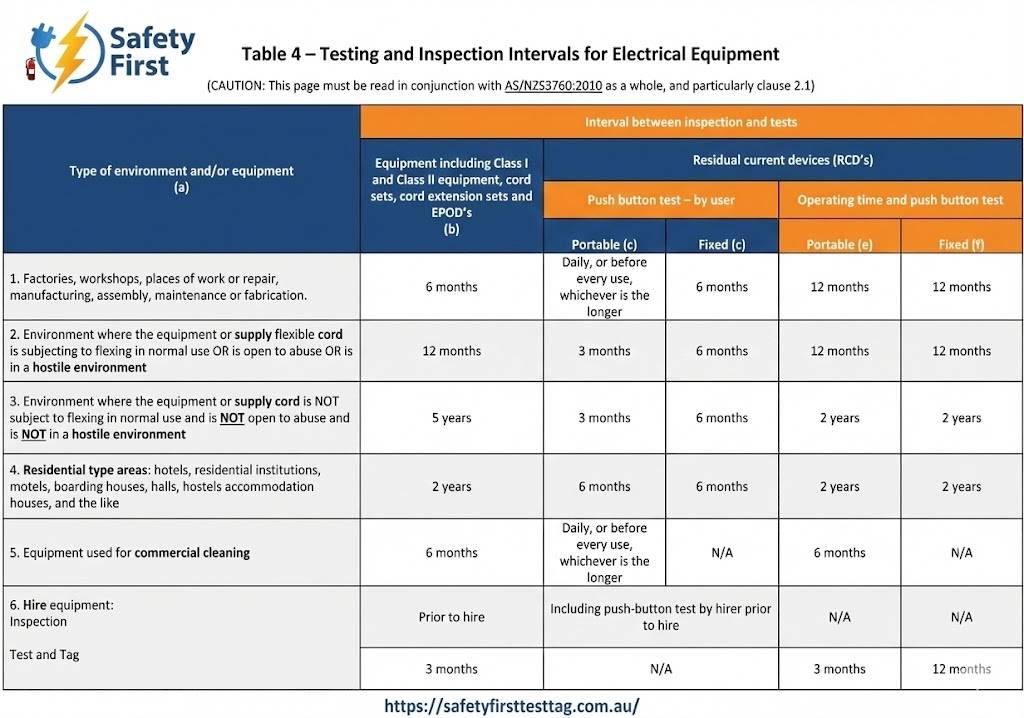

Understanding Re-Test Intervals

How often do you need to test? It depends on your ‘environment’ risk level as defined by AS/NZS 3760. We manage the schedule for you:

Environment Typical Frequency

- Construction / Demolition Every 3 Months

- Factories / Warehouses Every 6 Months

- Kitchens / Common Areas Every 12 Months

- Offices / Admin Areas Every 1-5 Years

Retest intervals/ Timeframes - Table 4 of AS/NZS 3760:2010

Our Electrical Testing Process

Why Choose Safety First?

Combined Fire & Electrical: We can test your Fire Extinguishers and Emergency Lights in the same visit. One booking, one invoice, zero hassle.

Minimal Disruption: For offices and servers, we use specialized procedures to test without causing data loss or downtime.

Reminder Service: We track your asset data and automatically notify you when re-testing is due, so you never fall out of compliance.

Frequently Asked Questions

What if an item fails? We immediately tag it ‘Danger – Out of Service’ and remove it from use. For minor issues (like a damaged plug), we can often repair it on-site. For major faults, we advise on replacement.

Do new appliances need testing? New equipment technically doesn’t need a test immediately, but it does need to be visually inspected and tagged as ‘New to Service’ to enter your safety cycle. We handle this for you.

Is it disruptive to my staff? We work around you. For busy retail or office environments, we can test early mornings or handle critical equipment during staff breaks.

Why Choose Safety First Test and Tag?

- Experience You Can Trust – With over a decade in the industry, we know compliance and workplace safety inside and out.

- Certified Technicians – Our team is fully trained, certified, and stays current with all WHS regulations.

- Affordable Compliance – Enjoy reliable, professional service at competitive rates.

- Reminder Service – We track your retest schedule and send timely alerts so you never miss a due date.

- Detailed Reporting – Transparent results and actionable recommendations for repair or replacement.

- Advanced Equipment – Using state-of-the-art tools from Seaward, we ensure fast and accurate testing every time

Stay Compliant and Safe with Safety First

Don’t leave electrical safety to chance. Trust the professionals at Safety First Test and Tag to keep your equipment compliant, reduce liability, and protect your people and business.

- SafeWork NSW

- Worksafe Victoria

- SafeWork SA

- WorkSafe WA