What Is Test and Tag?

Test and Tag is the process of inspecting and electrically testing portable appliances to ensure they are safe to use. In Australia, this practice is not just recommended—it’s a legal requirement under Work Health and Safety (WHS) Regulations to help prevent electrical hazards, shocks, and fires in workplaces.

The process involves two main steps:

- Visual Inspection: Checking the appliance for visible damage, wear, or defects.

- Electrical Testing: Using a portable appliance tester (PAT) to verify electrical safety and insulation integrity.

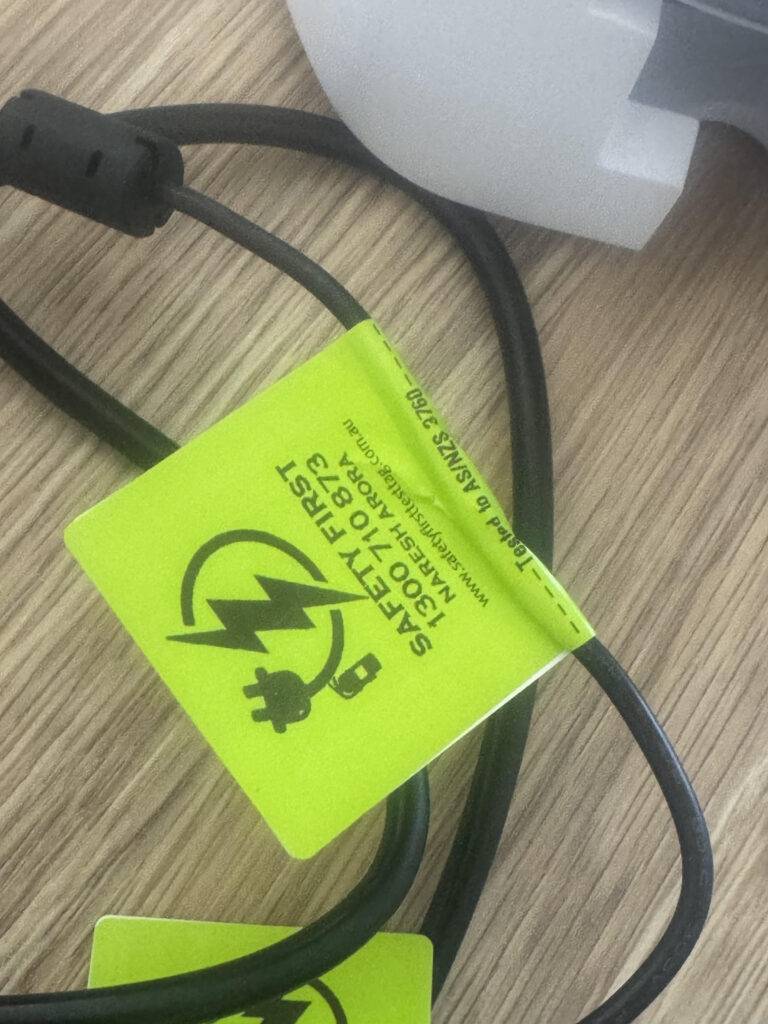

Each tested item is then tagged with a durable label showing the test date, next due date, and technician details.

Why Test and Tag Compliance Matters

Electrical equipment, especially in workplaces, can deteriorate over time. Faulty or unsafe appliances pose serious safety risks, including electrocution and fires. Regular testing and tagging ensure compliance with Australian Standards and create a safer environment for employees and visitors.

Benefits of staying compliant:

- Reduces risk of electrical accidents

- Meets WHS legal obligations

- Helps maintain insurance validity

- Prevents costly downtime from faulty equipment

- Provides peace of mind for business owners and staff

Relevant Australian Standards

The main standard governing testing and tagging is:

- AS/NZS 3760:2022 – In-service safety inspection and testing of electrical equipment and RCDs

Other relevant standards may include:

- AS/NZS 3012:2019 – Electrical installations on construction and demolition sites

- AS/NZS 3551:2012 – Management of medical electrical equipment (for biomedical environments)

Who Needs Test and Tag Services?

Test and Tag Compliance applies to all businesses, regardless of size or industry. Common workplaces include:

- Offices and corporate buildings

- Construction and demolition sites

- Factories, warehouses, and workshops

- Retail stores and shopping centres

- Healthcare and aged care facilities

- Schools, universities, and childcare centres

Essentially, any business that uses portable electrical equipment must ensure regular testing and tagging is completed by a qualified technician.

How Often Should You Test and Tag?

Testing frequency depends on the type of environment and level of risk. As a general guide (AS/NZS 3760:2022):

| Environment Type | Example | Test Frequency |

|---|---|---|

| High Risk | Construction, workshops | Every 3 months |

| Medium Risk | Factories, warehouses | Every 6 months |

| Low Risk | Offices, schools, retail | Every 12 months |

| Hostile Environment | Exposed to moisture, dust, or vibration | Every 6 months |

| RCDs (Safety Switches) | All workplaces | Every 6 months (Push Button Test) |

What Happens If You Don’t Comply?

Failure to comply with Test and Tag regulations can lead to:

- Fines or penalties under WHS laws

- Invalid insurance claims in case of an electrical incident

- Workplace accidents or injuries due to unsafe equipment

Regular compliance inspections protect your staff, customers, and your business reputation.

Choosing the Right Test and Tag Company

When selecting a provider, make sure they:

- Are qualified and licensed technicians

- Use calibrated test equipment

- Provide detailed compliance reports

- Offer reminders for future testing

- Follow AS/NZS 3760:2022 standards

At Safety First Test and Tag, we provide comprehensive testing for electrical appliances, emergency lights, smoke alarms, and fire equipment. Our goal is to ensure your workplace remains safe, compliant, and fully documented.

Final Thoughts

Test and Tag Compliance in Australia isn’t just about ticking a box—it’s about maintaining a safe working environment and meeting your legal obligations. Regular inspections by a professional ensure you’re protecting your employees, assets, and business from unnecessary risk.

Get Your Workplace Tested Today

If your business needs reliable Test and Tag Services in Geelong, Melbourne, or surrounding suburbs, contact Safety First Test and Tag today.